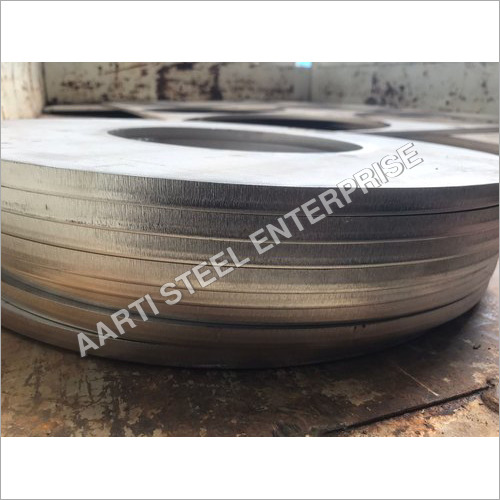

SS Laser Cutting 25 MM

उत्पाद विवरण:

कट 25 मिमी 25 मिमी 25 मिमी 12 मिमी 12 मिमी 2000x4000 के लिए नया लेजर इंस्टॉल मूल्य और मात्रा

- 1

कट 25 मिमी 25 मिमी 25 मिमी 12 मिमी 12 मिमी 2000x4000 के लिए नया लेजर इंस्टॉल व्यापार सूचना

- Vadodara

- , ,

- प्रति दिन

- दिन

- No

- Standard

- , , , , , , , ,

उत्पाद विवरण

SS Laser Cutting 25 MM

1. Material

-

Stainless Steel (SS) plate, thickness 25 mm

-

Grades commonly used: SS304, SS316, SS202 (as per requirement)

2. Cutting Capabilities

-

CNC fiber laser cutting for high precision

-

Clean edges with minimal burrs even at heavy thickness

-

Large sheet size handling for industrial components

3. Design & File Support

-

Custom profiles, slots, holes, and complex shapes

-

File formats: DXF, DWG, AI, CDR

-

Prototyping and bulk production options

4. Finishing Options

-

Brushed, mirror, or matte finish

-

Passivation or polishing for corrosion resistance

5. Applications

-

Heavy-duty machine parts

-

Industrial equipment bases

-

Structural components

-

Flanges, brackets, and support plates

6. Benefits

-

High strength and corrosion resistance of SS

-

Precision cutting without deformation

-

Faster turnaround compared to conventional cutting methods

Precision Cutting & Superior Edge Quality

Using high-powered laser technology, SS Laser Cutting 25 MM ensures each cut meets strict tolerance limits and delivers superior edge quality. The resulting components are burr-free and exhibit a smooth surface finish, ideal for aesthetic and functional requirements in critical industries.

Customization Meets Versatility

Whether handling complex shapes or sizes, our laser cutting service adapts to individual client needs through CAD or drawing specifications. This flexibility supports a wide range of projects for manufacturers, fabricators, and suppliers, ensuring efficient turnaround and accurate fabrication.

Advanced Material Performance

We process stainless steel grades 304 and 316, known for their exceptional corrosion resistance and durability in demanding environments. Both grades can be cut to desired thicknesses and dimensions, supporting everything from heavy-duty engineering components to architectural features.

FAQs of SS Laser Cutting 25 MM:

Q: How is SS Laser Cutting 25 MM performed on stainless steel sheets?

A: SS Laser Cutting 25 MM uses advanced fiber or CO2 laser machinery to cut stainless steel sheets up to 25 mm thick. The controlled, high-energy laser beam delivers precise and clean cuts, producing burr-free edges and smooth finishes according to the clients specifications.Q: What material grades are available for laser cutting, and how do they benefit different applications?

A: We offer stainless steel grades 304 and 316, or grades specified by clients. Grade 304 is valued for general corrosion resistance and affordability, while grade 316 provides enhanced resistance in marine and chemical environments, making both suitable for diverse industrial applications.Q: When should I choose SS Laser Cutting 25 MM over other cutting methods?

A: Laser cutting is ideal when high accuracy, minimal edge defects, and fast turnaround are priorities. Opt for SS Laser Cutting 25 MM for complex shapes or intricate designs, stringent tolerances (0.2 mm), and projects demanding a superior surface finish.Q: Where can these SS laser-cut components be used?

A: Laser-cut stainless steel components are widely used in industrial fabrication, construction, automotive sector, and engineering. Their precise dimensions and corrosion resistance make them suitable for components, housings, frames, panels and more in harsh or demanding environments.Q: What is the process for customizing SS Laser Cutting 25 MM parts?

A: Clients supply their drawings or CAD designs, specifying shape, dimensions, and grade requirements. Our team reviews the documentation, selects suitable sheet sizes per machine capabilities, and uses laser cutting to manufacture parts that match exact specifications.Q: How does the edge quality benefit my project?

A: The laser cutting process delivers burr-free, clean edges which reduce post-processing time and eliminate the need for secondary finishing. This results in faster assembly, improved safety, and a more polished end product for any application.Q: What are the main advantages of using stainless steel laser cutting services in India?

A: By leveraging high-precision laser technology and proven stainless steel grades, clients receive tailored solutions with rapid delivery, consistent quality, and robust corrosion resistance. Our services support dealers, manufacturers, and fabricators nationwide for a wide range of industrial needs.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese